Braceworks calculations and, in some cases, functionality depend upon creating connected rigging systems. As structural elements are placed in the drawing, they can automatically connect to similar elements with the same cross section. Trusses, straight trusses, curved trusses, and lighting pipes and ladders can connect to form a system. Connected to those items, hoists, dead hang objects, and loads (including lighting devices, speakers, speaker arrays, video screens, soft goods, and generic point and distributed loads) are also considered to be part of the system, and they move or adjust with the system automatically.

It is important to use the method of Changing the trim height of a system to adjust the height of structural systems and all connected objects properly. All of the items in the system move together, and the hoists’ and dead hang objects’ chain lengths are automatically adjusted if needed.

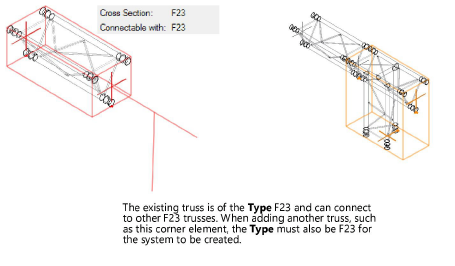

When using the Insert Truss tool, ensure that Auto Connect mode is enabled so that truss systems are automatically connected. Only compatible trusses can connect automatically. If the truss to connect does not cause an existing truss to highlight, it is because they are not compatible, or one of the structural elements does not have a valid Connectable with parameter.

In Auto Connect mode, trusses can only connect to compatible connectors:

● Spigot and connector plates can connect freely.

● Gable can only connect to fork.

● Spigot male can only connect to spigot female.

At insertion, Auto Connect mode automatically flips gable, fork, and spigot male/female trusses so they connect properly. An alert opens if a connection is not possible.

When adding other objects to the drawing, such as bridles, hoists, and loads, valid structural elements are highlighted in red, indicating that if placed there, the new object will connect to the system. Copying and pasting rigging objects, and even entire systems, also uses auto connect functionality to connect to existing systems.

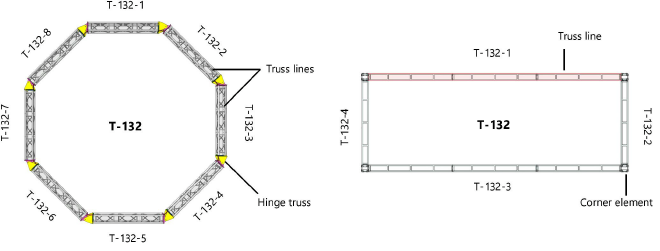

A completed rigging system consists of truss lines connected with hinges or corner elements to form a truss system, as shown in these simple illustrations. Example naming of truss lines and the system are shown; see Renaming truss systems for more information.

~~~~~~~~~~~~~~~~~~~~~~~~~